Debbie Dai

•Tough: 11 layers of co-extrusion blown film are accepted. Multilayer PA has excellent properties of tear resistance, puncture resistance and wear resistance.

•Flexible:With multi-layer co extrusion process, the film has excellent tensile properties and is relatively soft. The film lining material shows excellent flexibility in a wide temperature range. It can adapt to changes in pipe diameter and bending.

•Processable: Low friction films make installation easier; processable with hot steam and UV.

Description

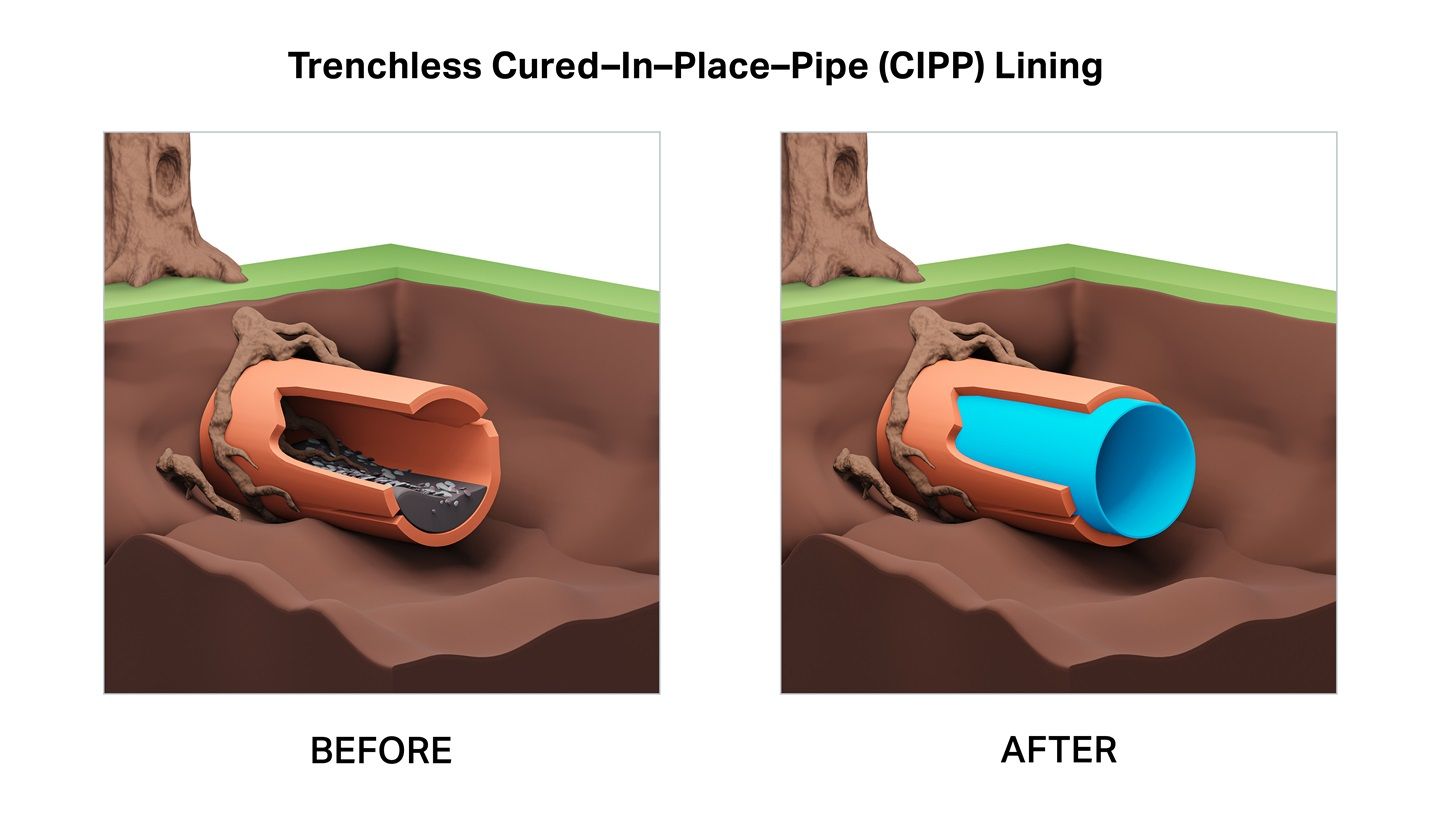

Anti UV CIPP lining film is a kind of functional film specially used for repairing various drainage pipes such as sewage pipes and rainwater pipes. It has the advantages of strong tensile strength, toughness and UV resistance, making the pipeline repair project simpler and extending the service life.

Material:PA/PE

Color:Yellow/Blue(Support customized color according to customer requirements)

Thickness:200micron(Support customization of thickness according to customer requirements)

Width:10cm-210cm

Structure:Symmetrical structure

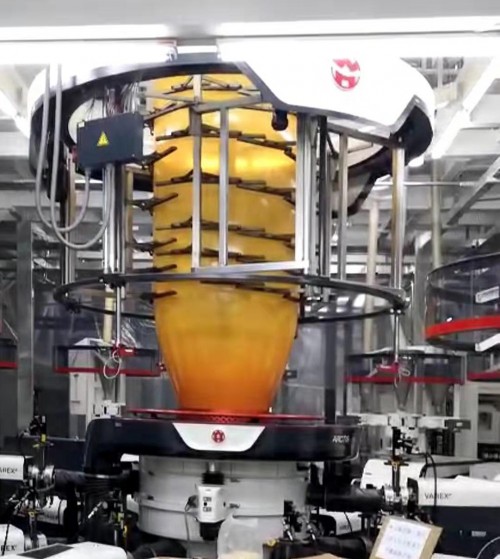

Processing technology

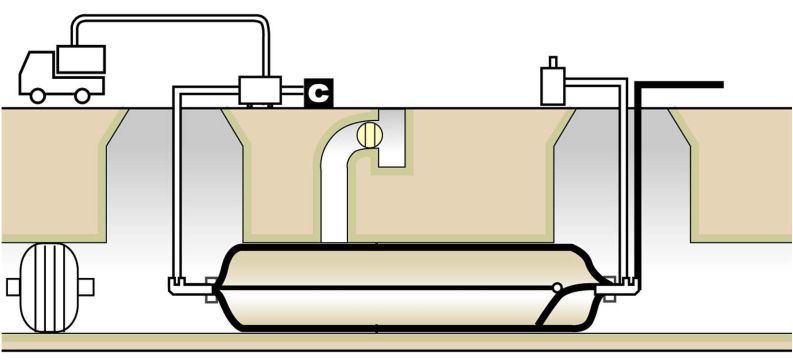

The ultraviolet curing method uses dragging method to drag the material hose into the underground pipeline. After being hardened by ultraviolet curing technology, a new lined pipe is formed in the existing pipe. This method requires a lot of tension when the material hose is pulled in. Generally, the plastic film is laid in the pipe in advance and then the construction is carried out.

1. Pull in (before pulling in the lined hose) the protective film of the lined hose

2. Pull in the lined hose

3. Inflatable lined hose

4.The UV curing process of the lining hose is monitored by video

Advantages

•Tough: 11 layers of co-extrusion blown film are accepted. Multilayer PA has excellent properties of tear resistance, puncture resistance and wear resistance.

•Flexible:With multi-layer co extrusion process, the film has excellent tensile properties and is relatively soft. The film lining material shows excellent flexibility in a wide temperature range. It can adapt to changes in pipe diameter and bending.

•Processable: Low friction films make installation easier; processable with hot steam and UV.

Applications

• Suitable for underground drainage pipes or channels.

• The section of the repaired object can be special shapes such as circle, oval, egg, square, etc.

•The inner diameter of the applicable circular pipe is usually DN150~1200mm, and the largest pipe diameter can be up to DN2000mm.

• The length of a single (usually) repair can reach 200m, and other lengths must be customized.

FAQ

Q1. What are your main products?

A1.We are flexible packing supplier, like buffer cushion packing, composite film , high separation vacuum co-extrusion film,vacuum bags

Q2.What is the main material of your products?

A2.The main material is PA,EVOH,PVDC,PE,etc.Our raw materials are imported from abroad,like DOW,ExxonMobil,Elite, famous brand company.

Q3. How do you test your product?

A3.Our company has a dedicated laboratory, we will have a professional product testing, we can also provide a monitoring data for each product report

Q4. What should be provided when placing orders?

A4.The material, size, thickness, width,length, printing art work

Q5.what's your product application?

A5.It is mainly used to package food, electronic accessories, chemical raw materials, plastic raw materials, such as meat, seafood, fishery products, etc.

Our products are also used in the field of China's aerospace industry, mainly in the production of astronauts' drinking water tanks in space. It is the only designated supply factory of China's aerospace drinking water tank films.

Contact Us

Candy Chen (International Trade Manager)

Mobile:0086-18895700158 Email: candy@hc-business.com

WeChat:(0086)18895700158 WhatsApp:(0086)18895700158