Debbie Dai

Food-grade raw materials

High transparent surface,

Texture design,

Roll bag design,

Strengthen resilience

★Product Description★

As we all know, vacuum bags are an environmentally friendly composite packaging material that uses a vacuum packaging machine to extract the air inside to keep fresh, prolong product shelf life, and inhibit the growth of bacteria in products.

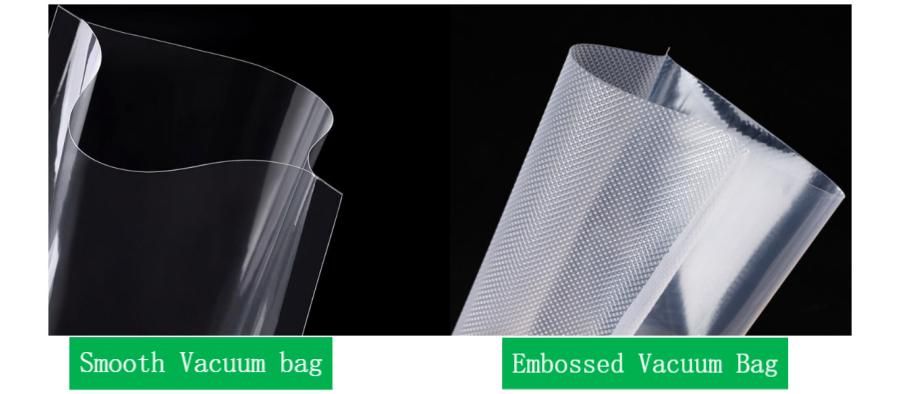

There are two types of vacuum bags on the market, one is called smooth vacuum bag, the other one is embossed vacuum bag.

Here we mainly talk about the comparison between smooth vacuum bags and embossed vacuum bags.

1. In appearance, the smooth vacuum bag is smooth on both sides, and the embossed vacuum bag is smooth on one side and textured on the other side.

2. Both of them can be vacuumed, but they need to be matched with different machines. smooth vacuum bags require a special vacuum machine for smooth surfaces, and embossed vacuum bags require a special vacuum machine for textured surfaces.

3. Compare the price:

The price of embossed vacuum bags is slightly higher than that of smooth vacuum bags due to different processing techniques.

★Product Specifications★

|

Material |

PA/PE, PA/PE/EVOH |

|

Structure |

11 Layer Co-Extrusion |

|

Thickness |

Smooth side 80um, embossed side 90um, 30% nylon, Support customer customization |

|

Bag Format |

3 Side Sealing |

|

Appearance |

Smooth side + Diamond embossed side |

|

Color |

Transparent, black, Support customer customization |

|

Temp Range |

-45 to 100 Degree |

|

Certification |

ISO, SGS, FDA, ROHS, BPA free |

|

Feature |

Low Oxygen Transmission Rate, Low Water Vapour Transmission Rate, High Puncture Resistance, Food Grade material, Direct Contact With Food |

|

Popular Size for bag |

100*150 120*200 150*200 150*250 170*250 200*300 250*300 250*350 300*400 300*500 Support customer customization |

|

Popular Size for Film roll |

120*5000 150*500 170*5000 200*5000 220*5000 250*5000 280*5000 300*5000 Support customer customization |

★Applications★

· – Raw Meat and Fish

· – Cooked Meat and Fish

· – Fish and Seafood

· – Cheese and Dairy products

· – Food-based liquids such as Soups, Gravies and Sauces

· – Powders and Granules such as coffee, tea, sugar and salts

· – Snacks such as crisps, popcorn, nuts and confectionery

· – Human Foodstuffs

· – Pet Foods

· – Fishing Baits

· – Microwaveable Foods.

★FAQ★

Q1. Are you a factury or trade company?

A1. We are professional manufacturer of multi-layer coextrusion barrier composite film, which has over thirty years' experience in this field.

Q2. what's your product equipment?

A2. 11 layer WH blown film line from German,

9 layer Macchi blown film line from Italy,

9 layer BE blown film line from Canada,

7 layer Macchi blown film line from Italy,

Q3.Can you provide sample?

A3. Yes, the sample is free, we will be very grateful if you can provide shipping cost.

Q4. How do you test your product?

A4.Our company has a dedicated laboratory, we will have a professional product testing, we can provide technical data sheet for each product

Q5. What should be provided when placing orders?

A5.The material, structure, size, thickness, width, length, and order quantity.

★Contact Us★

Debbie, Dai (International Trade Manager)

Mobile:0086-18715575829 Email: debbie@hc-business.com WeChat:008618715575829 WhatsApp:0085252745717